Home Products Control Cabinet Electrical Control Cabinet Custom Order

Kuntai Technology's Custom Control Cabinet Process

1. Initial Consultation

The custom - control - cabinet process at Kuntai Technology begins with an in - depth initial consultation. Our professional team engages with clients to comprehensively understand their specific requirements. This includes learning about the intended application of the control cabinet, such as whether it will be used in industrial automation, power distribution, or other fields. We also gather details about the control functions needed, like the type of equipment to be controlled, control precision requirements, and the number of input and output signals.

2. Design Phase

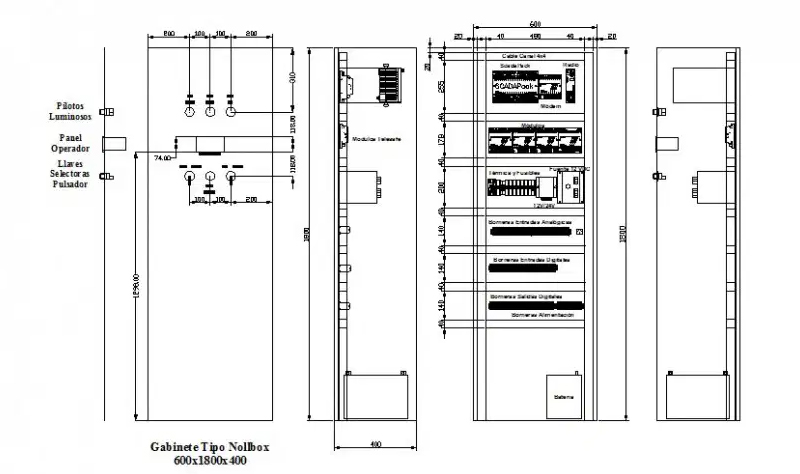

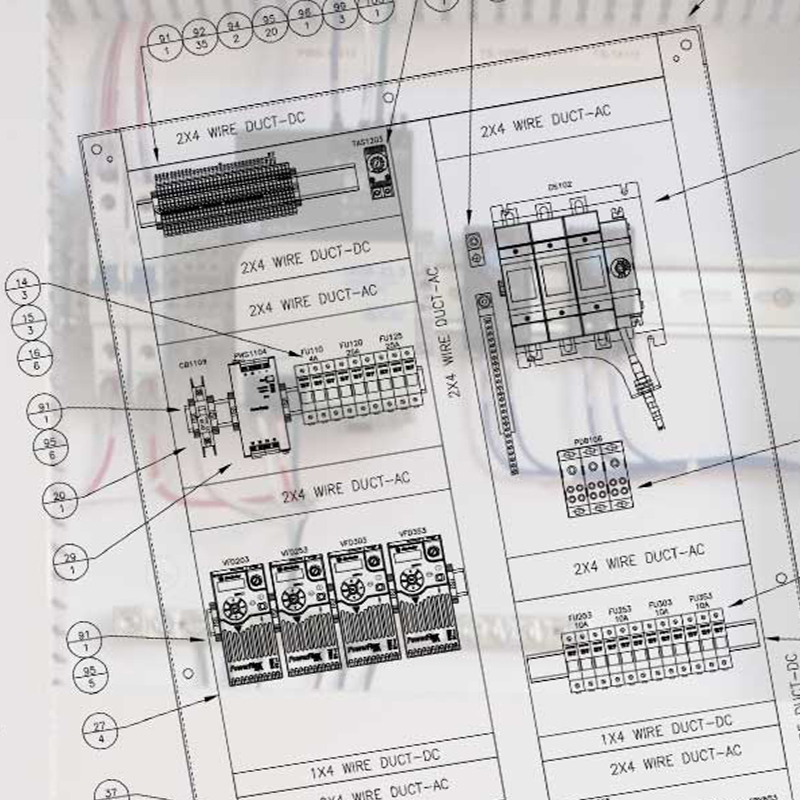

Based on the information collected in the initial consultation, our engineering team commences the design phase. We create detailed electrical schematics for the control cabinet. This involves carefully selecting the appropriate electrical components, such as programmable logic controllers (PLCs), variable - frequency drives (VFDs), circuit breakers, and relays, to ensure optimal performance and compatibility.

Simultaneously, we design the mechanical structure of the cabinet. We determine the size, material (such as stainless steel or cold - rolled steel), and the protection level (e.g., IP54, IP65) according to the client's usage environment. Considerations are also given to aspects like ventilation and heat - dissipation to maintain stable operation of the electrical components.

3. Quotation and Contract

Once the design is complete, Kuntai Technology provides a detailed quotation to the client. The quotation includes all costs associated with the custom - made control cabinet, such as material costs, manufacturing expenses, and quality - testing fees. After the client reviews and negotiates the quotation, and both parties reach an agreement on the price, delivery time, quality standards, and after - sales service terms, a formal contract is signed.

4. Manufacturing

In the manufacturing stage, our skilled workers first process the cabinet body according to the design drawings. This involves operations like cutting, welding, and surface treatment to ensure the cabinet has high mechanical strength and an aesthetic appearance.

Then, the electrical components are precisely installed inside the cabinet. Our technicians follow strict wiring standards to ensure that all wires are correctly connected, neatly arranged, and well - insulated. After the installation and wiring are completed, a preliminary functional test is carried out to check if the basic control functions are working properly.

5. Quality Inspection

Quality inspection is a crucial step in the process. Kuntai Technology adheres to strict quality - control standards, both in - house and in line with relevant industry standards. We conduct comprehensive inspections on the electrical performance, such as voltage stability, current - carrying capacity, and electromagnetic compatibility. Mechanical aspects, including the firmness of component installation and the integrity of the cabinet structure, are also carefully examined. Any issues identified during the inspection are promptly rectified.

6. Packaging and Delivery

After passing the quality inspection, the control cabinet is carefully packaged. We use appropriate packaging materials and methods to protect the cabinet from damage during transportation. Once packaged, the control cabinet is shipped to the client's designated location in a timely manner.

Even after delivery, Kuntai Technology's service doesn't end. We provide professional installation guidance and user training to ensure that the client can use the control cabinet correctly and safely. Additionally, we offer long - term after - sales service to address any potential problems that may arise during the client's use of the product.