Home Products Industrial Humidifier Industrial Air Humidifier KUNAT Manufact

Introduction to Industrial Humidifiers

1. Definition

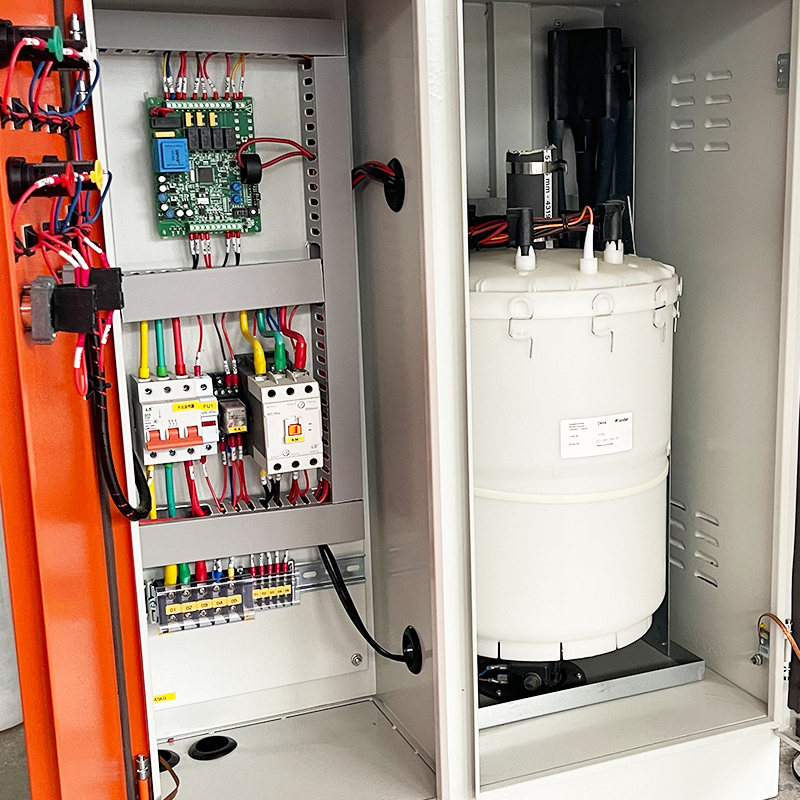

Industrial humidifiers are specialized devices designed to increase the moisture content in industrial environments. By accurately controlling the humidity level, they play a crucial role in maintaining optimal conditions for various industrial processes, equipment operation, and product quality.

2. Working Principle

Most industrial humidifiers operate based on different physical mechanisms. For example, ultrasonic humidifiers use high - frequency vibrations to break water into tiny droplets, which are then released into the air to increase humidity. Evaporative humidifiers work by passing air over a wet surface, where the water evaporates and mixes with the air. Steam humidifiers, on the other hand, generate steam by heating water, and the steam is then introduced into the air to humidify it.

3. Types

Ultrasonic Humidifiers: These are popular for their high - efficiency and quiet operation. They can quickly increase humidity in a relatively small to medium - sized industrial space. The fine water droplets produced by ultrasonic vibrations are easily absorbed by the air, making them suitable for applications where rapid humidity adjustment is required.

Evaporative Humidifiers: They are energy - efficient and often used in large - scale industrial areas. The evaporation process is natural and can provide a continuous and stable increase in humidity. They are also relatively easy to maintain as they do not produce mist, reducing the risk of water - related damage to equipment.

Steam Humidifiers: These are suitable for applications that require precise humidity control and high - humidity levels. Steam can be quickly distributed in the air, and the humidification effect is relatively uniform. However, they usually consume more energy due to the need for water heating.

4. Application Scenarios

Textile Industry: In textile manufacturing, maintaining the right humidity is crucial. Appropriate humidity can prevent static electricity, reduce yarn breakage, and improve the quality of fabrics. Industrial humidifiers are used to ensure smooth production processes and high - quality finished products.

Printing and Packaging: In the printing and packaging industry, humidity affects the quality of paper and ink adhesion. By controlling humidity, industrial humidifiers can prevent paper from warping, ensure clear printing, and improve the overall quality of packaging products.

Food Processing: Humidity control is essential in food processing to prevent food spoilage, maintain the freshness of products, and ensure food safety. Industrial humidifiers help create a suitable environment for food storage, processing, and packaging.

Electronics Manufacturing: In the electronics industry, static electricity caused by low humidity can damage sensitive electronic components. Industrial humidifiers are used to maintain proper humidity levels, reducing the risk of electrostatic discharge and improving product yield.

5. Maintenance

Regular Cleaning: To ensure optimal performance, industrial humidifiers need to be cleaned regularly. This includes removing any accumulated dirt, scale, and bacteria from the water tank, humidifying components, and air ducts. Cleaning can be done using appropriate cleaning agents and tools, following the manufacturer's instructions.

Water Quality Monitoring: Using clean and suitable water is crucial for the proper operation of industrial humidifiers. Monitoring the water quality regularly can prevent the formation of scale and ensure that the humidifier functions efficiently. In some cases, water treatment equipment may be required to improve water quality.

Component Inspection: Periodically inspecting key components such as sensors, pumps, and heating elements (for steam humidifiers) can help detect potential problems early. Replacing worn - out or damaged components in a timely manner can extend the lifespan of the industrial humidifier and ensure its continuous and reliable operation.